LSAW Pipe

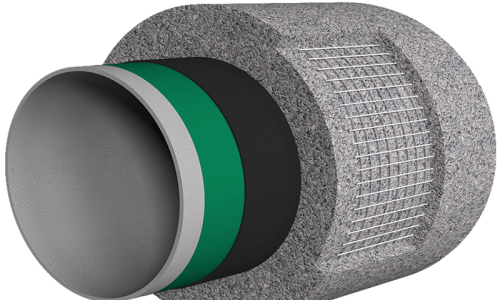

Longitudinal Submerged Arc Welding (LSAW) Processes Longitudinal Submerged Arc Welding (LSAW) is an advanced manufacturing technique primarily used for producing high-pressure steel pipes with substantial wall thickness. This article examines the LSAW pipe manufacturing process, including the JCOE and UOE forming methods, material properties, quality inspection procedures, and primary applications. LSAW pipes offer superior pressure resistance and durability, making them the preferred economical solution for demanding environments. These pipes serve critical infrastructure in oil and natural gas transportation, water supply systems, sewage treatment, and central heating networks where reliability under high internal or external pressures is essential.

| |||||

Outside Diameter | Thickness | Capacity (MT annually) | Length | Grade | Pipes Ends |

16″ (457 mm) to 60″ (1500mm) | 6mm to 30 mm | 200,000 (0.2 Million) | Up to 18,000 mm (18 Mtr) | API 5L GR upto X80, Upto ASTM A 252, ASTM A53, ASTM A572. ISO 3183 | Plain/ Bevelled/ Threaded |

Steel Pipe Manufacturing Steel pipes are elongated hollow tubes designed to transport products between locations. They are manufactured through two primary methods: welded pipe production and seamless pipe production. Both processes begin with raw steel being cast into more manageable forms such as slabs, hot billets, or flat strips. The material is then either stretched to create seamless pipes or formed by joining the edges of flat steel strips with welds.

When operational conditions demand high wall thickness due to elevated internal or external pressures, LSAW pipes typically represent the most cost-effective solution. These pipes excel in high-pressure environments and offer excellent low-temperature corrosion resistance. The diameter range for LSAW pipes is more extensive than Electric Resistance Welding (ERW) pipes, typically spanning from 16 inches (406 mm) to 60 inches (1500 mm).

| |||||

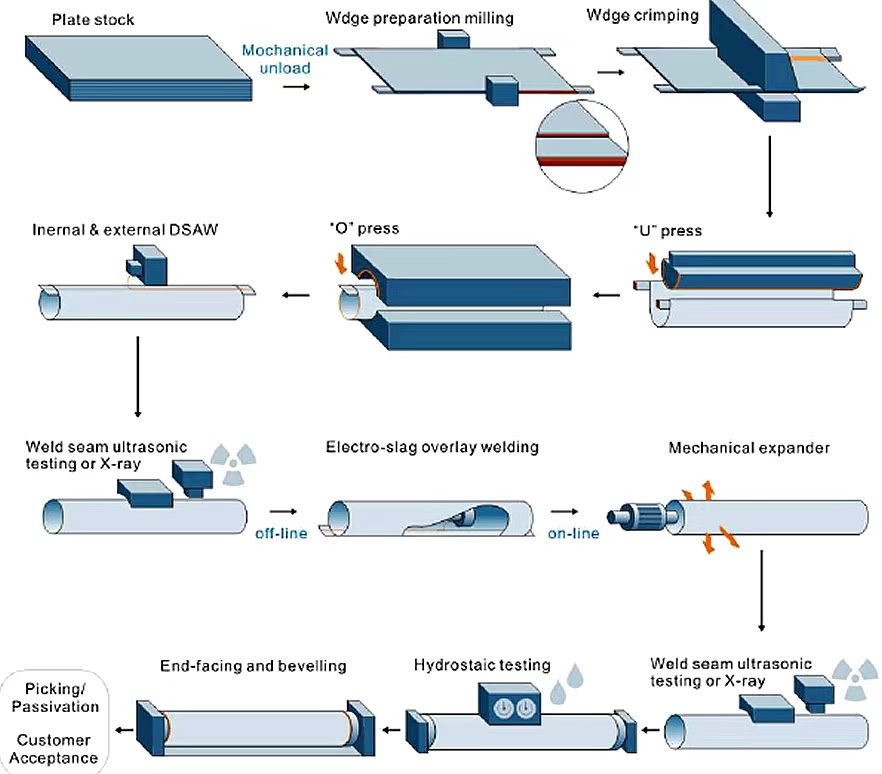

LSAW Pipe Manufacture Process The production of longitudinal submerged arc welded pipes involves bending and welding wide steel plates. These plates are typically sourced from leveled hot-rolled coils and are processed through either JCOE or UOE forming methods. In these processes, the steel plate is progressively shaped to resemble the letters "J," "C," "O," or "U" before final expansion. | |||||

UOE Manufacturing Method | |||||

| |||||

The UOE method is a common approach for producing longitudinally welded large-diameter pipes. The process begins with beveling the longitudinal edges of steel plates using carbide milling equipment. These beveled plates are initially formed into a U-shape using a U-press, then further shaped into an O configuration with an O-press. | |||||

Quality Control and Testing LSAW pipes undergo rigorous inspection procedures to ensure quality and reliability. These include: o Chemical component analysis o Mechanical properties testing (ultimate tensile strength, yield strength, elongation) o Technical property evaluations (flattening test, bending test, blow test, impact test) o Exterior size inspection o Hydrostatic testing o X-ray examination

| |||||

Applications of LSAW Steel Pipes LSAW pipes serve numerous essential applications across various industries. The primary uses include: o Oil and natural gas transportation o Gas distribution networks o Central heating systems o Water supply infrastructure o Sewage treatment facilities o Low-pressure fluid delivery systems These applications highlight the versatility and importance of LSAW pipes in critical infrastructure development and maintenance.

| |||||