Piling Steel Pipe

PILING WHAT ARE STEEL PIPE PILES? Steel pipe piles are driven vertically into the ground and used as a deep foundation for large commercial and industrial buildings. Pipe pilings transfer the structural load of the foundation to the soil below. STEEL PIPE PILING USES Pilings are used to support extremely large or heavy buildings where topsoil cannot offer adequate support. They are also used when the land area is too small to accommodate spread footers or foundations. Pilings are driven vertically, deep into the ground where the soil is more tightly packed. STEEL PIPE PILING TYPES: · Anchor pile · Bearing pile · Bridge pile · Building pile · Foundation pile · Marine and dock pile · Micro pile · Screw pile

|

|

STEEL PIPE PILING APPLICATIONS PALM BRI’s steel pilings are used as deep foundation piles for power stations, high-rise buildings, civil engineering construction, bridges, marine structures, harbors, and other industries & applications. PALM BRI Industry Corporation maintains a large inventory of steel plate ready to be converted into piling to your exact specifications.

| STEEL PIPE PILING SIZES To manufacture our high-quality steel pipe piling, we roll steel plates – between 0.312 inch and 2 inches thick – into round, steel cylinders. Using 3 manufacturing processes, PALM BRI Industry can supply pipes between 21mm up to 3048mm in diameter at thicknesses between 2.1mm up to 100mm. These include LSAW pipe, SSAW spiral pipe and ERW pipe. A wide range of steel grades. PALM BRI has delivered many thousands of tons of pipe piling around the world. |

Steel Pipe Piling | ||

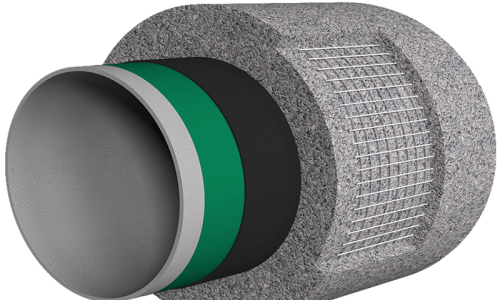

Deep foundations are utilised when the soils in the shallow region do not have the strength to support the loads from the structure. Pipe piles are frequently used in deep foundations and transfer the loads from building to stronger soil layers found deep underground. The surface loads are resisted through skin friction and point bearing of the pile. The pipe piles can be driven with open or closed ends, with points or plates. If driven with plates, the pipes can then be filled with rebar and concrete to boost the strength to the pile. Pipe piles range in size from several millimetres to several metres in diameter and can be easily spliced to create piles over 100 metres in length. Using 3 manufacturing processes, PALM BRI Steel can supply pipes between 21mm up to 3048mm in diameter at thicknesses between 2.1mm up to 100mm. These include LSAW pipe, SSAW spiral pipe and ERW pipe. A wide range of steel grades. PALM BRI has delivered many thousands of tons of pipe piling around the world. | ||

Manufacturing Processes

| ||

Longitudinal Submerged Arc Welded LSAW Pipe | Spiral Submerged Arc Welded SSAW Pipe | Electric Resistance Welded ERW Pipe |

LSAW Pipes are formed by rolling a discrete length into a cylinder and welding it both longitudinally and laterally. This method can produce the largest and thickest pipe sections, which can be used as load bearing piles, combination wall piles or other applications.

| SSAW Pipe are formed in a spiral and welded both inside and outside continuously. They are typically used as King Piles for Combination Walls and also Dredging Pipe. | ERW Pipes are manufactured by rolling the raw plate into a cylinder and then passing a current through to fuse the two ends. They are typically used for fencing, scaffolding and line pipes for fluis and gases. |

Product Studies

| ||

|  |  |

STEEL PIPE PILING FABRICATOR WHY CHOOSE PALM BRI INDUSTRY?

We PALM BRI offer reliable, flexible service with efficient lead times and shipping via truck, rail or water. Steel pipe is lightweight and affordable. Our 50,000m2 of manufacturing space, a diverse lineup of equipment, and a highly experienced workforce provides

· On-site flame planer for quick cutting of plate steel · Plate rolling capability up to 4” thick · Welding stations capable of pipe from 1'’-120’ in diameter and 2-150 mters long · Onsite, ERW,LSAW, SSAW and DSAW-trained welding personnel Submit files, specs and details about your project to our team. To achieve quick turnaround, product customization, and the quality required by our clients, we have developed full manufacturing capabilities on site. |