ERW Pipe

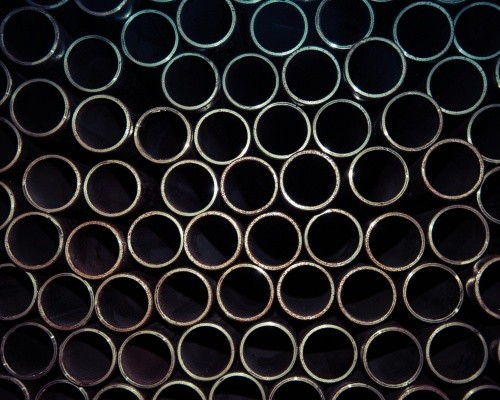

ERW Pipes ERW pipes are extensively used in agriculture, industry and construction activities like scaffolding and casing in bore wells. These are used for conveying water, gas, crude oil and chemicals at various pressures and densities over long distances. Considering the challenging and varied applications, the pipes are produced to meet very high standards of both national and international specifications. Quality assurance begins at the raw material stage and continues right through all the manufacturing operations, till the Piles are packed for dispatch. The quality assurance department is fully backed by modern laboratory for various metallurgical and chemical tests, and test hours for testing physical properties. It has been awarded the prestigious ISO 9001:2015 certificate for its quality systems.

|  | |||||||

NPS | Thickness | Capacity (MT Per annum) | Length | Specification | Pipes Ends | |||

½” to 24″(15 nb) to | 1.0 mm to | 800,000 | 3000 mm to | National / International specifications including API5L upto X-80, PSL1&2, API 5CT H40, J55, K55 PSL1, EN : 10255/10219, EN : 10217-1, ASTM A 53. BS EN – 39, ASTM A 500 ASTM A 252, ASTM A 795, etc. | Plain, Bevelled, Threaded, Roll-Grooved | |||

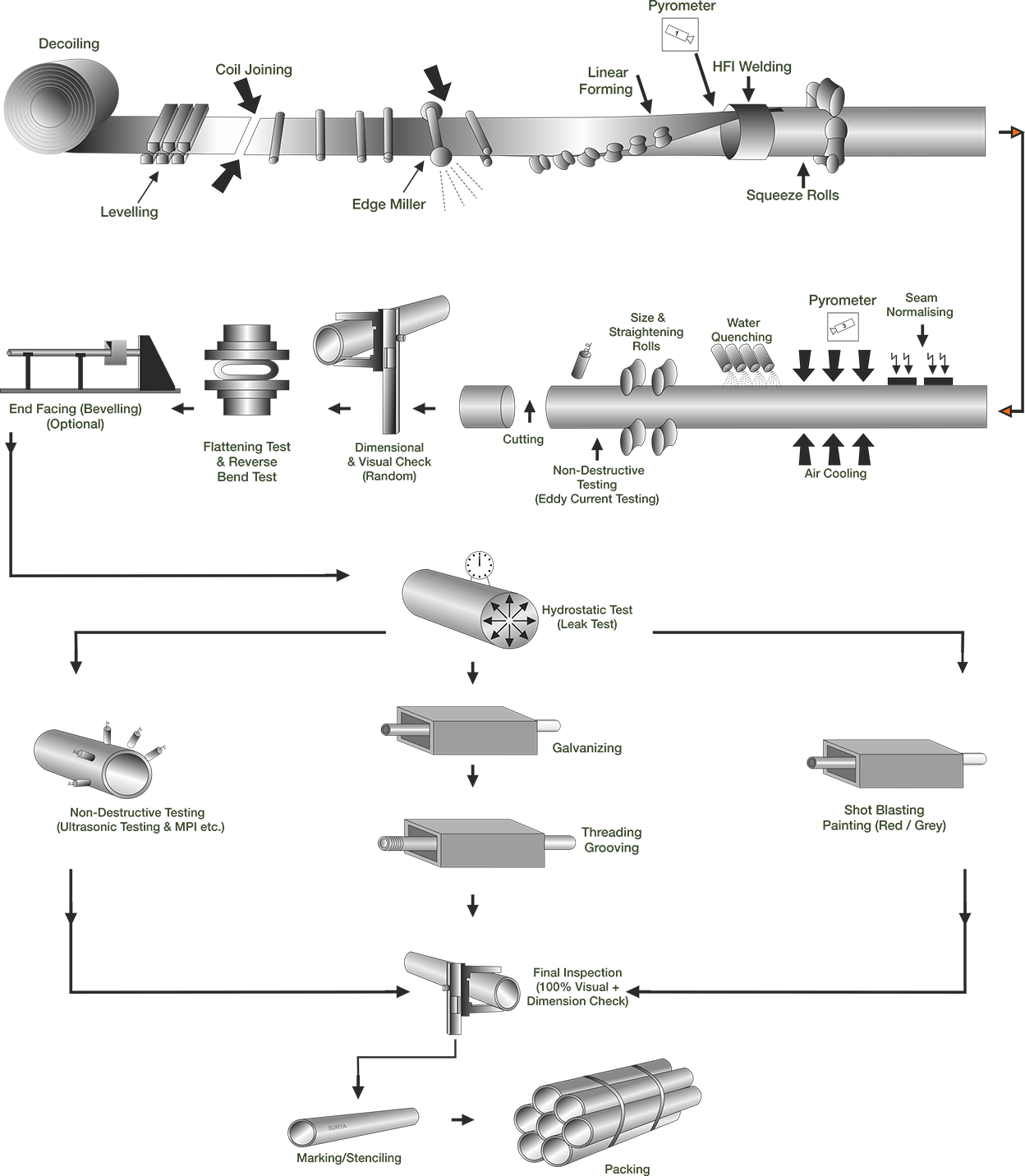

Manufacturing Process of ERW Pipes ERW pipes are made from HR Coils manufactured & supplied by reputed major steel producers. After being longitudinally slitted & edge preparation, the strip is progressively formed into a circular shape by passing it through a series of forming rolls. Continuous welding is carried out by a high frequency inducting welding machine, and the seam is formed by fusing the edges without any filler metal. The weld bead reinforcement (inside), is removed. if needed. The welded pipe, after cooling, are cut in appropriate length after attaining its roundness and specified outside diameter. The pipes are conveyed to the finishing bay for finishing, testing and inspection. Hydro testing of pipes is undertaken to detect leaks and fissures prior to galvanizing and threading. The pipes are subsequently galvanized/black varnished/threaded as per specification/client requirement. Customer satisfaction drives PALM BRI in everything that it does. No wonder, its commitment to the high quality of its pipes commences right from the selection of raw material and continues at every stage of manufacturing process till the finished product. The inspection procedures evaluate each pipe for surface finish, perfection of weld, correct diameter wall thickness, length and weight. | ||||||||